MESCO Prepainted Galvanized | High-Quality PPGI Steel Coils Manufacturer | Custom Colors & Coatings Available

- Model

- single Color PPGI PPGL

Item specifics

- FACE BOOK

- MESCO STEEL

- +86 15134565556

- mesco@mescogroup.com.cn

Review

Description

Pre-painted galvanized steel(PPGI coil)

What is PPGI?

PPGI (Pre-Painted Galvanized Iron) is a type of coated steel that consists of a galvanized steel substrate with a layer of colored paint applied through a continuous coating process. It features excellent corrosion resistance, decorative appeal, and workability. MESCO STEEL provides high-quality PPGI products with smooth surfaces and a wide range of colors, widely used in construction, appliances, and transportation industries.

MESCO STEEL exports PPGI to countries worldwide, trusted by clients globally. Major export destinations include: Vietnam, India, UAE, Saudi Arabia, Mexico, Russia, the Philippines, South Africa, Chile, Indonesia, USA, Brazil, Turkey, Egypt, and Malaysia.

PPGI/PPGL Specifications & Coatings

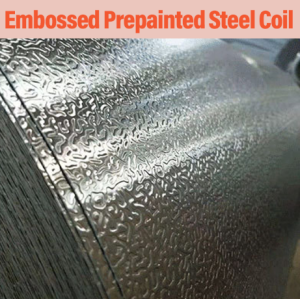

Our prepainted galvanized steel coil comes in a range of thicknesses from 0.1 to 6.0 mm and widths from 600 to 1,800 mm. Furthermore, we offer different surface treatments, such as matte, glossy, embossed, textured, etc.Our products have been exported to over 90 countries, including the Philippines, Turkey, Brazil, Colombia, Australia, Russia, Libya, Iran, New Zealand, Poland, and others. Please do not hesitate to contact us to obtain the latest price!

Recommended Upgrade: Powder Coated Steel

Powder-coated steel is an upgraded version of PPGI, using electrostatic spraying technology for a more uniform coating, stronger adhesion, zero solvent emissions, and better environmental performance. It is ideal for projects requiring superior weather and corrosion resistance.

PPGI Coil Description

| Item | PPGI (Pre-Painted Galvanized Iron) |

| Deliver port | Tianjin |

| Brand Name | MESCO STEEL |

Thickness | 0.1-6.0MM |

Width | 600-1800MM |

Length | as clients' requests |

Grade | DX51D、DX53D |

Coating types | PE、SMP、HDP、PVDF |

Coating thickness | Obverse side 10-35μm , Reverse side 5-14μm |

Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

Delivery Time | 3-45 days |

Application | matte, glossy, embossed, textured, etc. |

Coil Weight | 5-10 MT |

MESCO Advantages

Standard colors and specifications are in stock, ensuring fast delivery.

A wide variety of paint types available to meet project requirements.

Customizable paint film thickness options for flexible solutions.

Color coated steel sheet Key Features

1.Durability & Corrosion Resistance: PPGI combines the strength of galvanized steel with a protective painted layer, ensuring long-lasting resistance to corrosion and environmental damage.

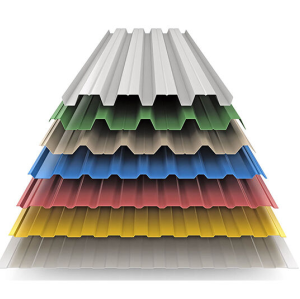

2.Wide Range of Colors & Finishes: Choose from a variety of colors and finishes, including matte, glossy, and textured surfaces, to meet your specific project requirements.

3.Excellent Formability: PPGI is easy to process, making it ideal for applications such as roofing, siding, panels, and automotive parts.

4.Sustainable & Eco-Friendly: The high-quality coating is environmentally friendly and can be recycled, reducing the carbon footprint of your project.

5.Custom Sizes & Specifications: We offer PPGI in a variety of thicknesses, widths, and lengths to accommodate a wide range of needs. Custom options are available for large orders.

PPGI coil colors

1..Single-color pre-painted sheet

Prepainted galvanized steel coil,comes in a variety of colors, with the most popular options including sky blue, grey, silver, traffic red, moss green, olive green, signal white, and more. In addition, there are hundreds of other colors to choose from, allowing you to find the perfect shade for your project.

To ensure color consistency in your project, it’s highly recommended that you purchase PPGI steel from the same supplier. Even if you’re using the same color code, such as RAL5015, the color may vary across different suppliers or even between batches from the same supplier. By sourcing all your materials from a single supplier, you can minimize the risk of any color discrepancies and ensure a uniform appearance across your project.

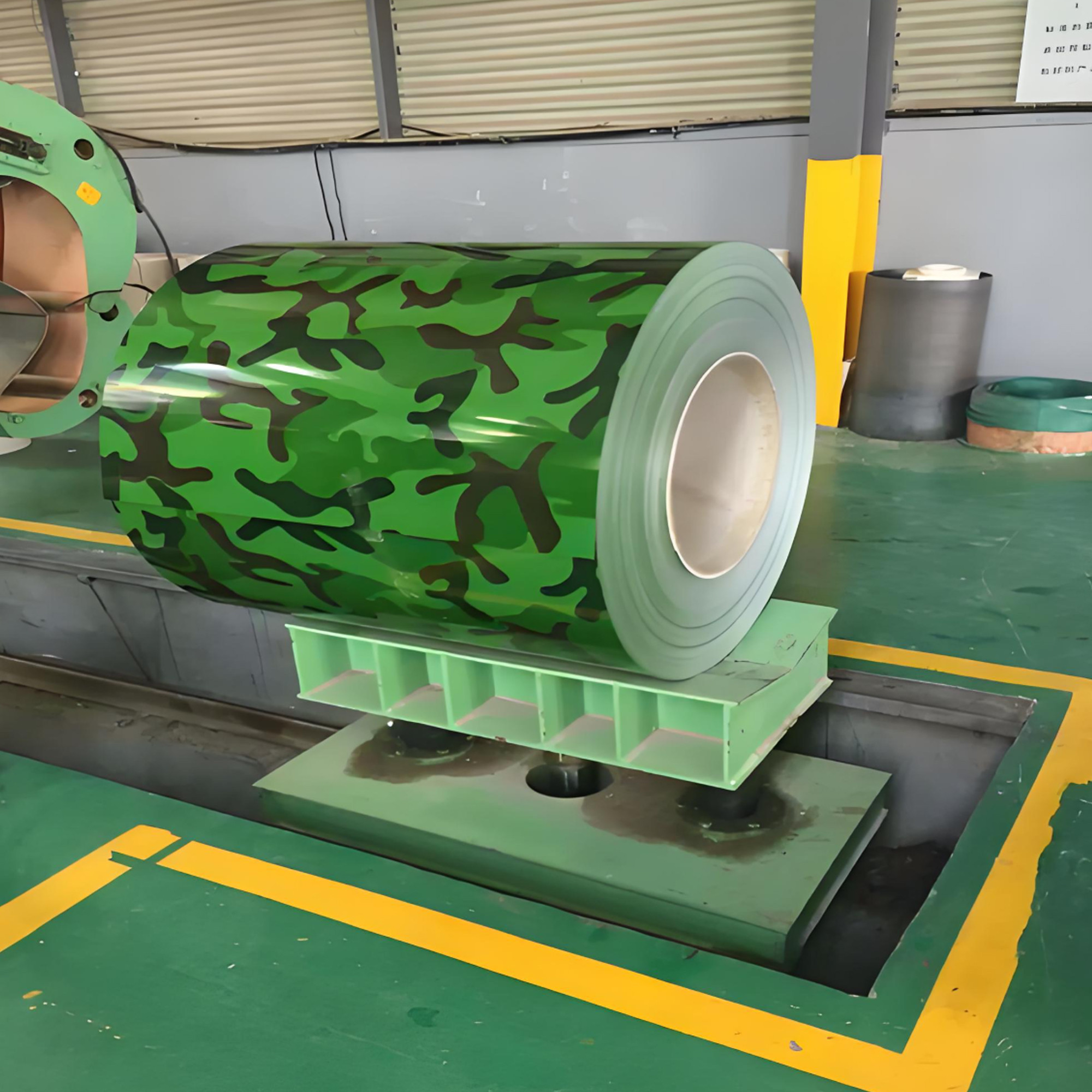

2.Popular Patterns

Some of our most popular designs include grass, wood grain, flowers, brick, and traffic signs, among others. Below, you’ll find some examples of the products we’ve customized for our clients.

Grass pattern PPGI coil is primarily used for fencing applications, particularly for temporary fences outside construction sites. Wood grain metal is a popular choice for wall panels, door panels, window frames, and other architectural elements due to its natural appearance and durability. Flower patterns are popular in furniture or other decoration purposes. You can choose according to your needs.

Applications of PPGI

Pre-painted galvanized steel coil can be further processed into plain, profile, and corrugated sheets, which can be used in many areas, for example:

1.Construction Industry: Used for roofing, wall cladding, and pre-engineered buildings, offering aesthetic appeal and functional performance.

2.Automotive Industry: Essential for making car parts such as body panels, doors, and frames due to its lightweight and durability.

3.Home Appliances: Widely used for refrigerators, washing machines, and other household appliances that require durable, rust-resistant materials.

4.Furniture Manufacturing: Ideal for the production of durable, weather-resistant furniture and fixtures.

5. Other industries, such as roller shutters, advertising boards, traffic signboards, elevators, whiteboards, etc.

Why Choose Our PPGI?

1.Premium Quality: We use high-grade galvanized steel and advanced painting technology to ensure every coil meets the highest industry standards.

2.Customization: Our team works closely with clients to offer tailored PPGI solutions that meet specific project needs.

3.Reliable Delivery: We provide fast and reliable shipping, ensuring your orders are delivered on time and in perfect condition.

4.Competitive Pricing: Offering cost-effective pricing without compromising on quality, ensuring you get the best value for your investment.

How to Choose the Coating for PPGI Steel Coils?

1.Coating Type Selection

PPGI steel coils commonly feature polyester (PE), high-durability polyester (HDP), silicone-modified polyester (SMP), polyvinylidene fluoride (PVDF), and acrylic coatings. PE offers cost-effectiveness for indoor use, HDP provides enhanced weather resistance for outdoor applications, while PVDF is ideal for extreme environments. Select the appropriate type based on corrosion resistance, cost, and intended use.

2.Coating Thickness Requirements

The standard coating thickness ranges from 5~25μm (both sides), directly impacting corrosion resistance. For general environments, 10~15μm is sufficient, while highly corrosive areas (e.g., coastal or industrial zones) require ≥20μm. Balance performance and budget, as excessive thickness increases costs.

3.Color and Surface Finish

Light colors (e.g., white) reflect UV rays, extending service life, whereas dark colors absorb heat and degrade faster. Choose from glossy (easy to clean), matte (scratch-resistant), or textured (hides imperfections) finishes based on aesthetic and functional needs.

4.Substrate and Galvanization Matching

The substrate's zinc coating (e.g., GI or GL) determines rust prevention. Thicker zinc layers (e.g., Z275) enhance corrosion resistance. Cold-rolled steel offers high strength, while aluminum-zinc alloy (GL) provides superior corrosion protection—select based on processing methods.

5.MESCO STEEL Customization Support

Choose MESCO STEEL as your trusted supplier for technical expertise. We recommend coatings tailored to your processing techniques (stamping, bending) and offer customized solutions (e.g., special backside treatment) to optimize costs. Contact MESCO for dedicated sales support to ensure accurate order fulfillment.

How to Order

1.Contact Us: Reach out to our sales team to discuss your requirements and receive a personalized quote.

2.Product Customization: Choose the specifications, including thickness, color, and finish.

3.Place Your Order: Confirm your order and provide delivery details.

4.Fast Delivery: We will ship your order promptly, ensuring timely delivery to your location.

FAQs

Is PPGI resistant to rust?

Yes, the galvanized coating protects against rust, while the paint layer adds additional protection.

Can PPGI be used outdoors?

Absolutely! PPGI is perfect for outdoor applications like roofing and cladding due to its superior resistance to environmental elements.

What thickness of PPGI is suitable for roofing?

For roofing applications, we recommend a thickness between 0.4mm and 0.8mm for optimal durability.